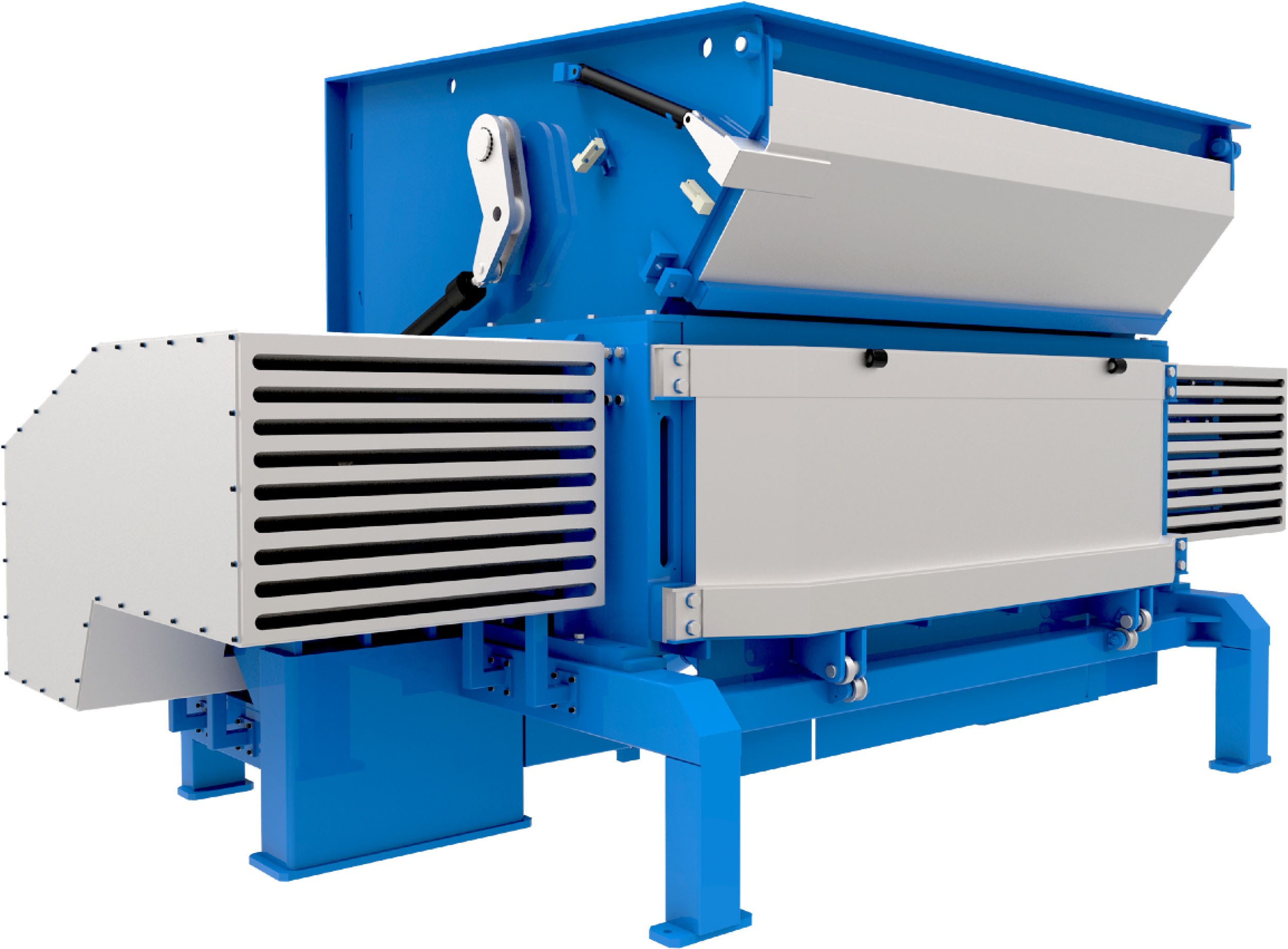

Optima 206/256/306

Universal shredders

Optima Recycling Solutions

Description

Optima 206/256/306 is a single shaft shredder of medium speed. Electric drive and hydraulic pendulum feeder, with low energy consumption. The pendulum feeder press the material against the rotor, equipped with fixed teeth that cut the material against anvil steels.

The feeder, is operated by a last generation hydraulic system with proportional valve or hydraulic variable displacement axial piston pump. The process is set from software in the PLC.

Obtains fractions: 10- 150 mm. Capacity: 30 - 60 m3/h.

Key benefits

Highlights of the Optima shredders: Low electrical consumption • Low dust and noise level • Very simple maintenance • It is not necessary with rotor cooling • Can process material down to 10mm in one step • Technical availability from 96% to 98% • Possibility to add water in the inlet

Shreds materials

Recomended use: Industrial waste • Urban waste • Logs • Laminates • Bark • Wood waste • Paper • Craft • Plastic • Textiles

Textile

Plastics

Wood

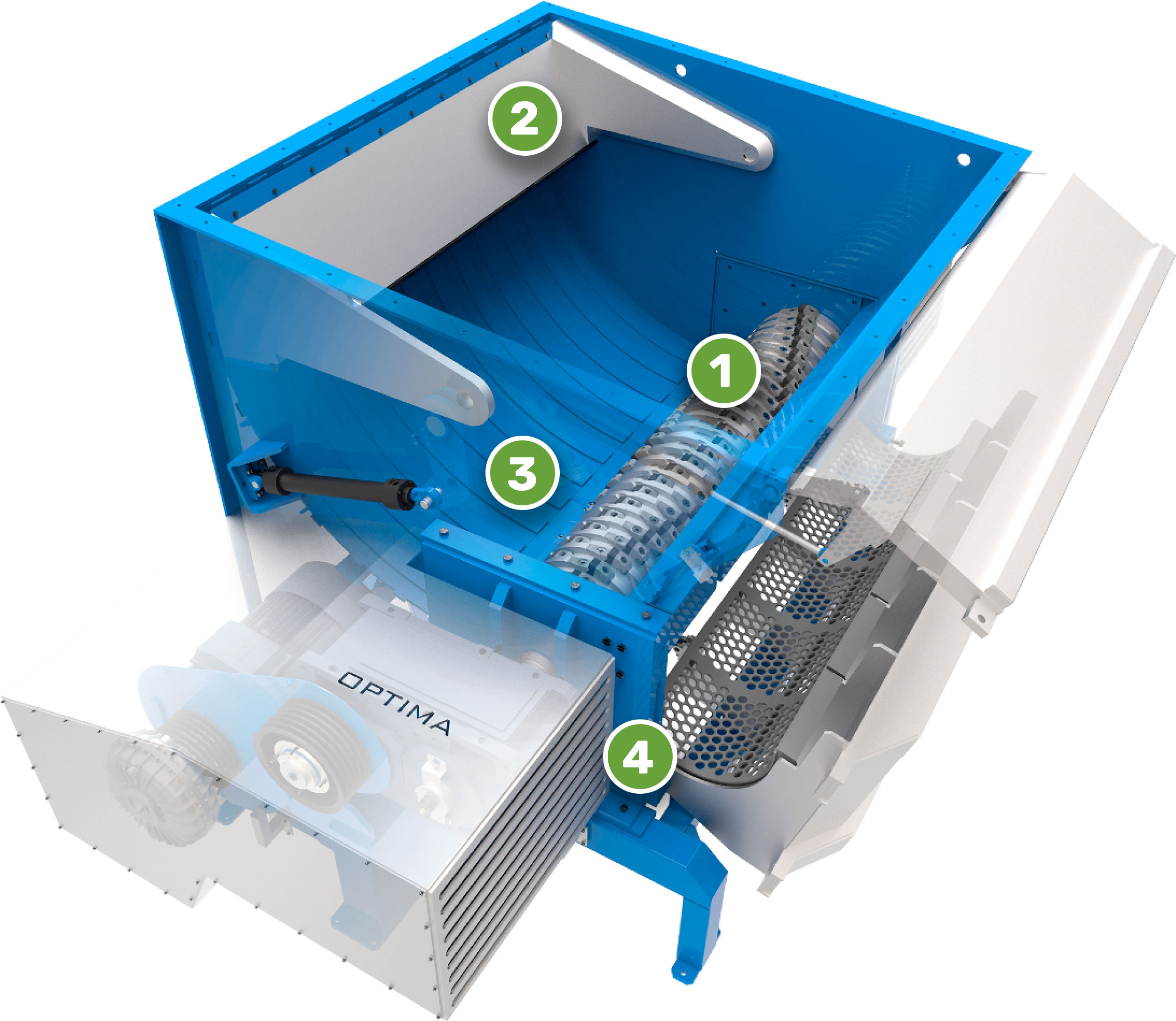

Overview

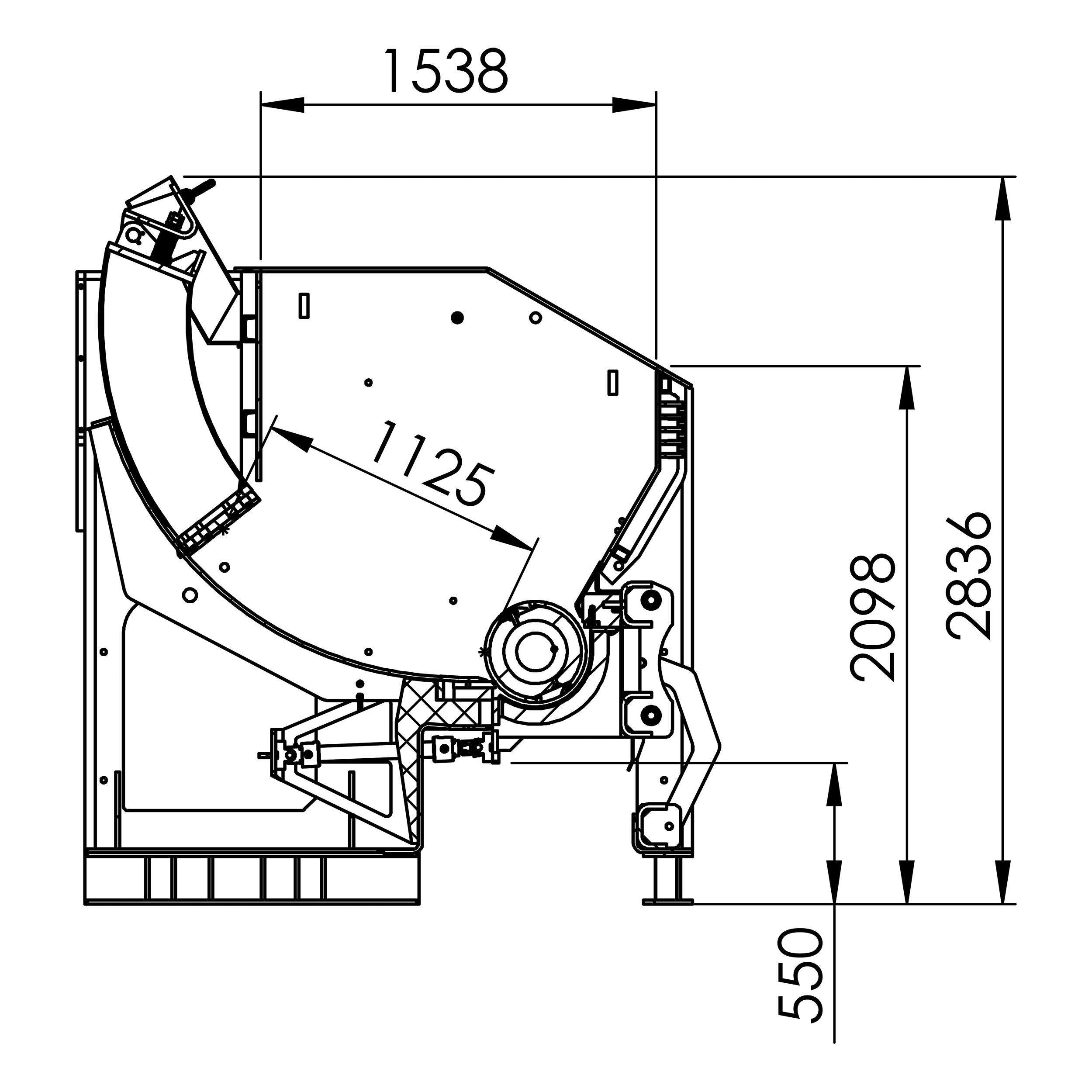

1. Rotor. With rings, maximum cutting surface and cooling.

2. Feeder. Pendulum, interior and with anti-jamming system.

3. Cutting chamber. Large shredding space.

4. Bearing. Displaced, to avoid contamination.

In action

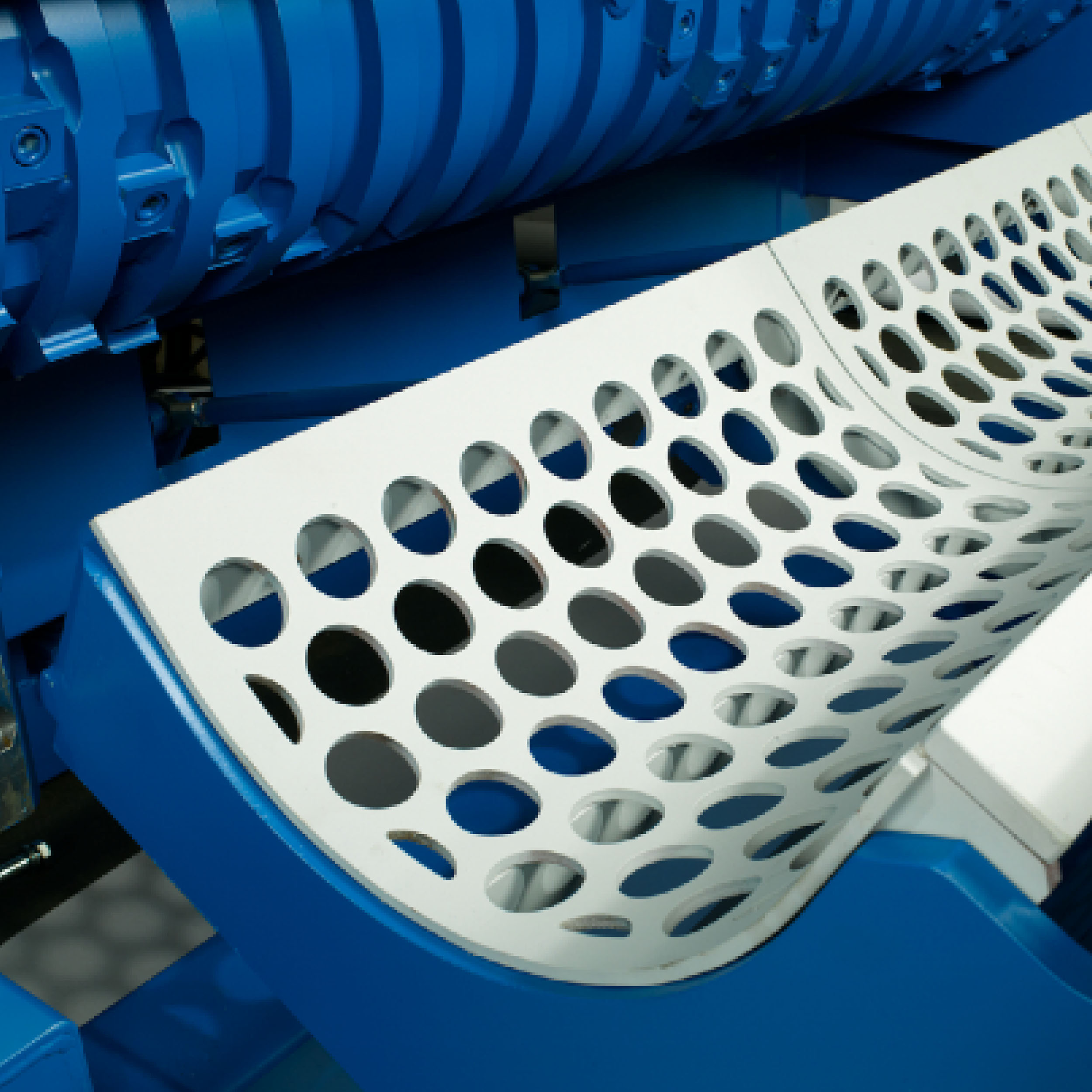

Rotor

Screen

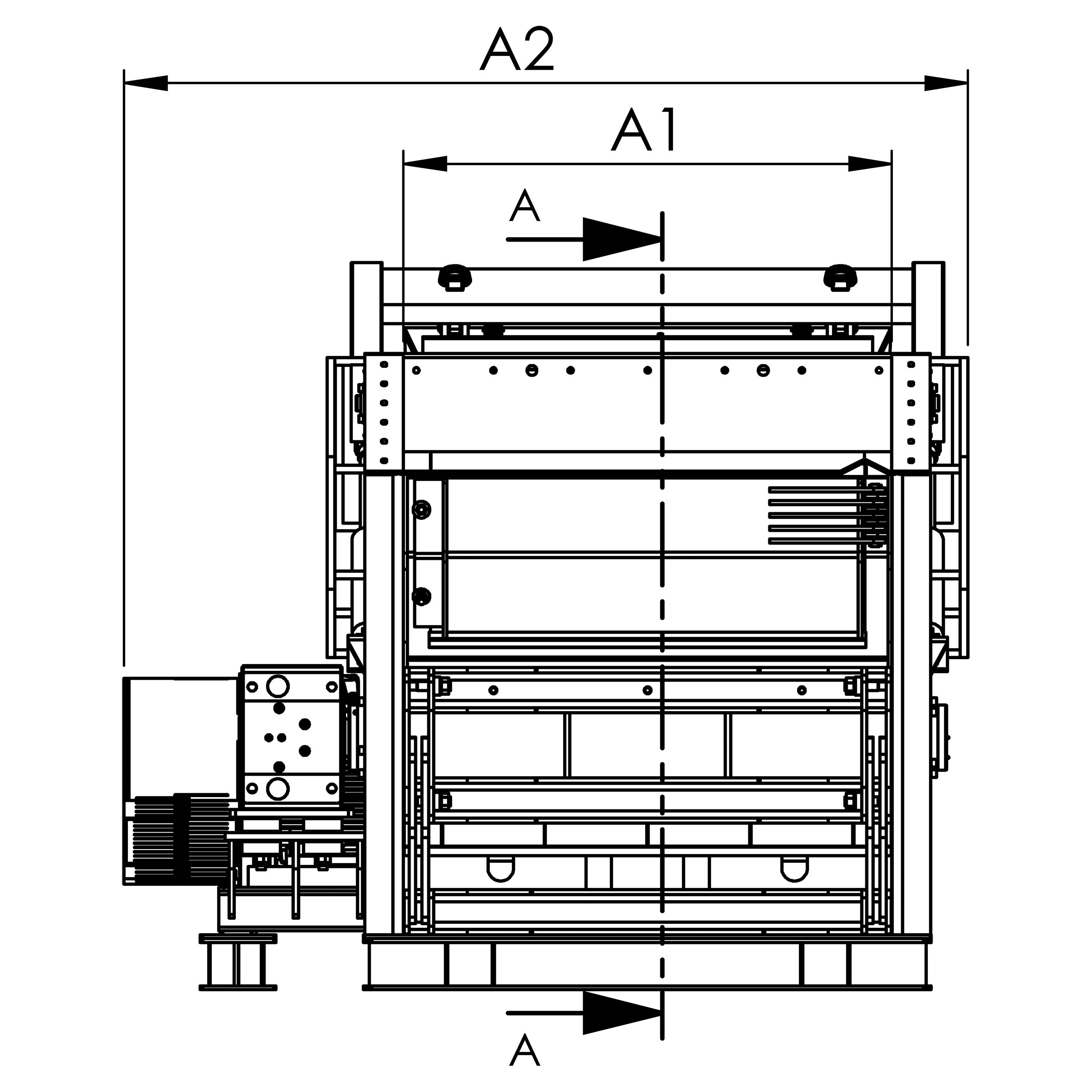

Technical data

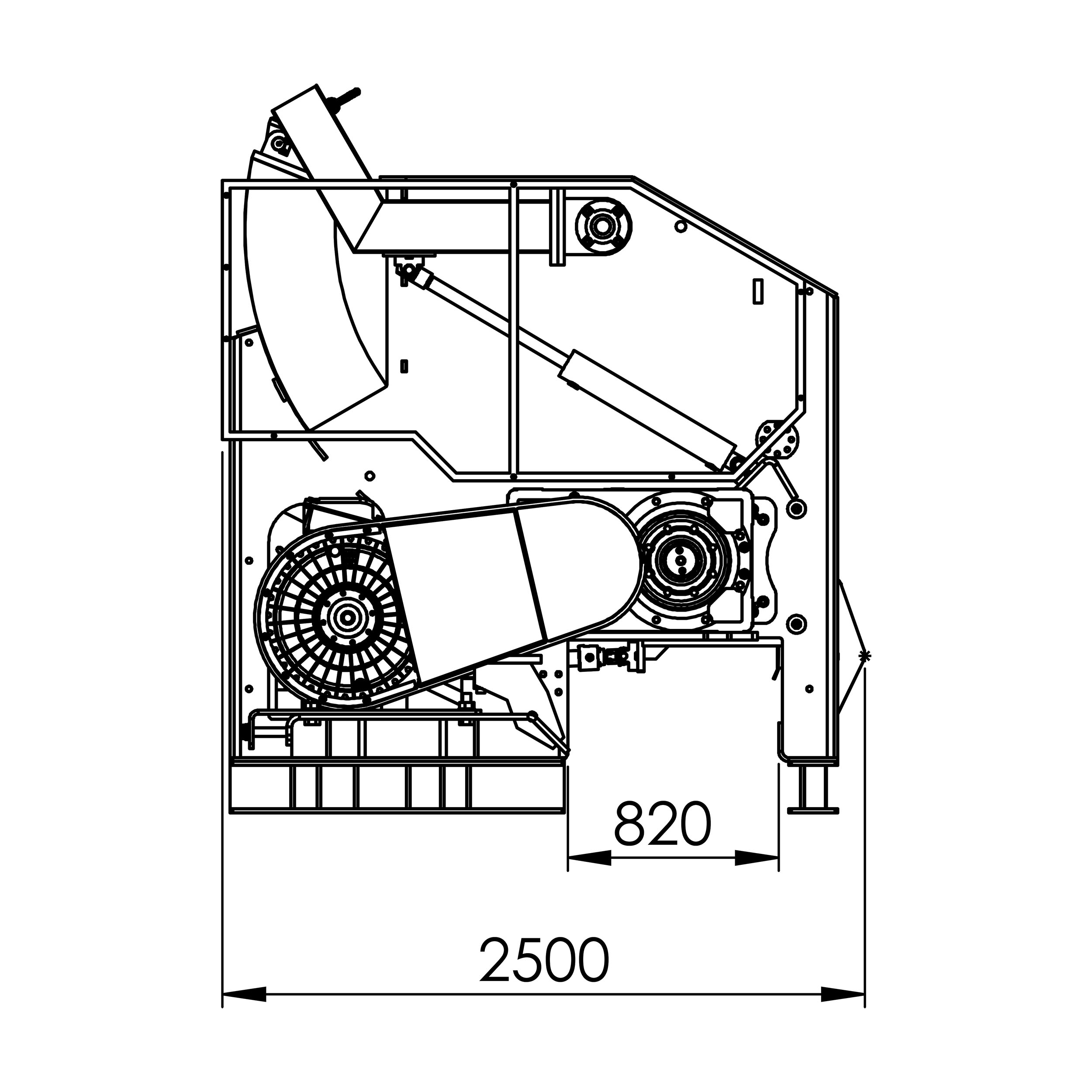

| Model | Dimensions | Inlet | Power | Rotor | Teeth | Weight |

| Optima 206 | A1:2.000mm A2: 4.200mm |

2.000x2.150mm | 132-160kW | 2.000x600mm | 80/60 | 15ton |

| Optima 256 | A1:2.500mm A2: 4.900mm |

2.500x2.150mm | 160-264kW | 2.500x600mm | 100/75 | 18ton |

| Optima 306 | A1:3.000mm A2: 5.400mm |

3.000x2.150mm | 160-264kW | 3.000x600mm | 120/90 | 19ton |

Optional add-ons

Optima Shredders can be equipped with a variety of complements to suit your process • Hydraulic sieve basket • Front service door • Hydraulic feeder table • Second vertical pusher • Extraction system • Enlarged hopper • Variable frequency drive, or the acronym AFD • Torque limiter, by friction • Hydraulic coupling