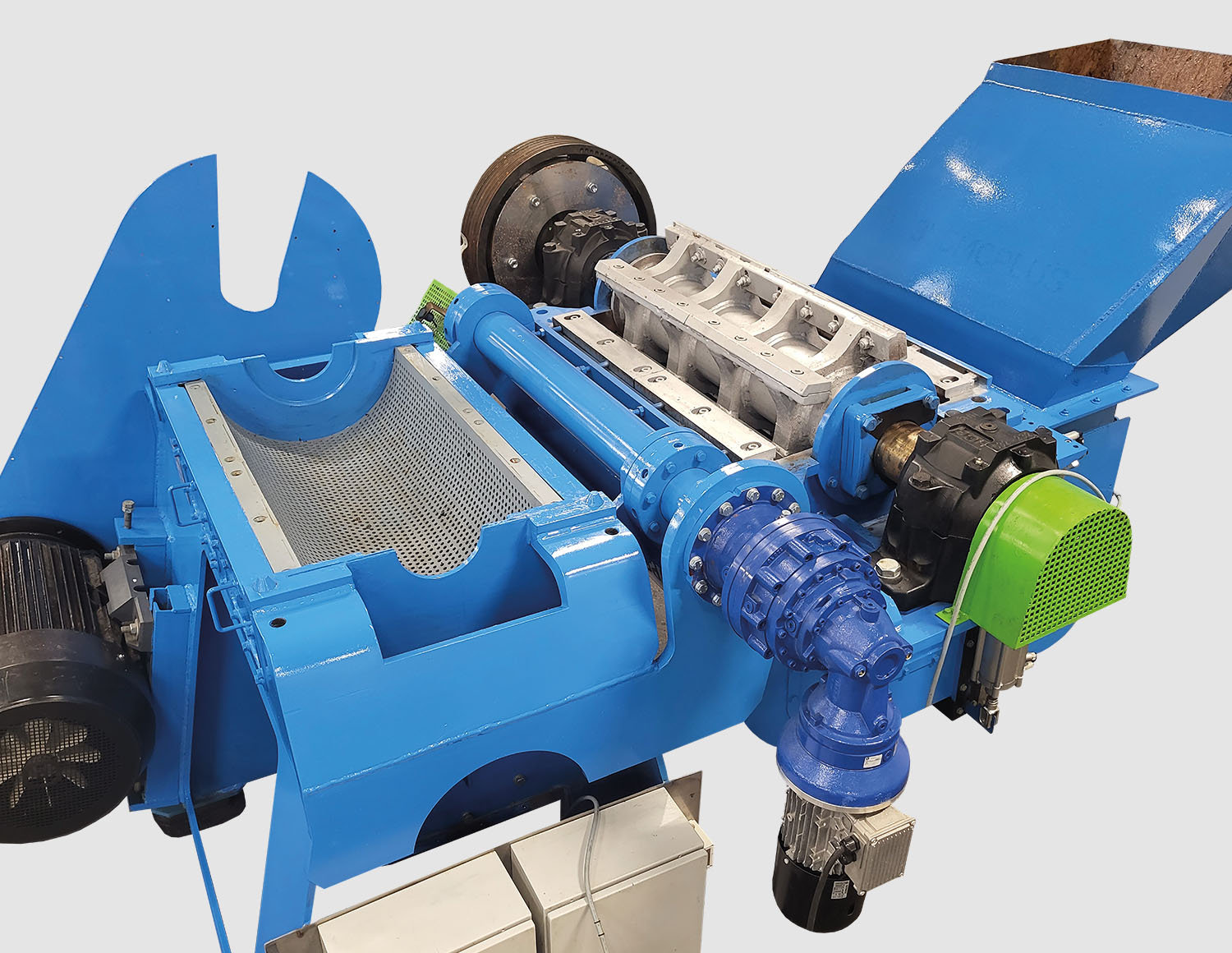

BioSep®

Unique pre-treatment technology

We turn organic waste into green energy

BioSep® – the next generation process to convert food waste into valuable biomass for biogas production

BioSep® is a unique pre-treatment technology that enables separation of Organic Material from plastics and other packaging materials in existing waste streams. The end product from this process is a virtually plastic free biomass suitable for anaerobic digestion for biogas production.

The BioSep® technology makes it possible to remove food packaging and other undesired materials without any human effort or pre-handling. This provides our customers with a process that cost effectively solves the pre-treatment and Separation which is becoming ever more important while striving to achieve an efficient anaerobic digestion in biogas production. Click here to learn more about the The BioSep® technology.

BioSep® is the core component in our BioPrePlant® System. BioPrePlant® Systems are “All-In-One” systems that are customized to satisfy our clients every need. The “All-In-One” system enables acceptance of a wide range of feed stock from food waste, providing flexibility, consistency and minimal down time in the plant due to lack of raw material. At the same time our BioPrePlant® System stands for a unique and groundbreaking performance and quality in pre-treatment of food waste, with proven performance data previously unknown to the industry. Click here to learn more about the BioPrePlant® System.

Easy service and maintenance.

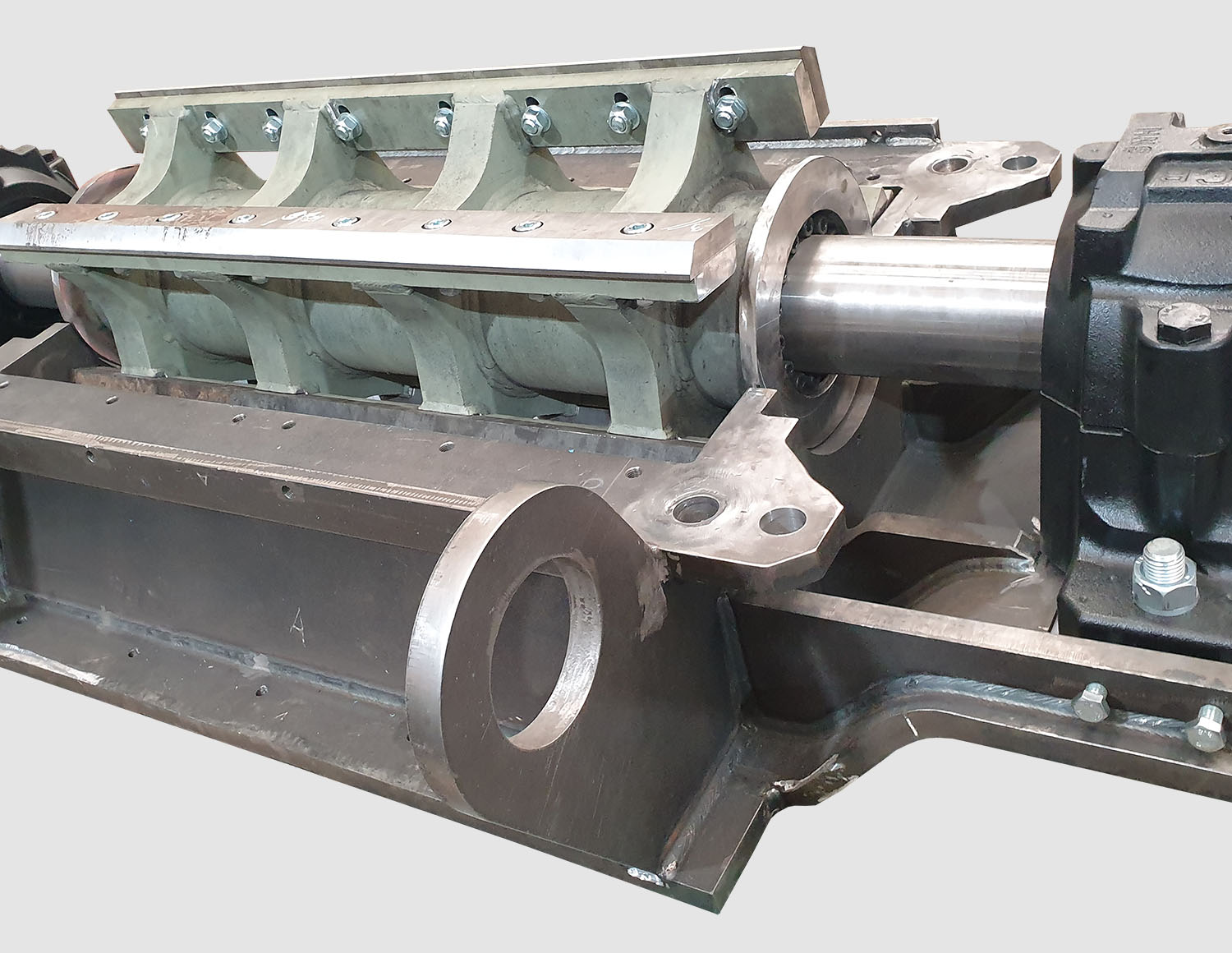

Heavy duty rotor.

Unique patented technology.

10 Technical highlights

1. Best separator technology on the market for a biogass pre-treatment plant

2. Very easy service and maintenance

3. Unique patented technology

4. Minimum 20 years working time with regular service/service contract

5. Slow rotation

6. Sedimentation technology

7. High quality on the substrate – normally 15 – 17 in dryness

8. Up to 9 tons per hour

9. Compatible to all types of pre-treatment systems

10. Simple integration into existing process lines

Other key benefits

Highlights of the BioSep®: Minimal amount of water in the biosubstrate • Minimal loss of digestible material in the rejects • No need for human interventions and de-packaging • Perform on all kinds of food waste • Performs with all kinds of household collection systems • All-in-One • Optimal utilization of resources • Foot print • Cost efficient • Problem free operation • Adjustable standard layout

Automation and control

All BioPrePlant®-Systems are delivered with a customized automation and control system. We offer our clients a process plant that to a great extent is operated automatically, with a minimum of operator interventions needed.

10 Environmental highlights

1. Multiwaste separator

2. Highest level of plastic sorting on the market

3. Clean plastic for recycling

4. Process water for cleaning can be used

5. More or less no loss of organic material

6. Dry reject

7. Most pure substrate on the market

8. Low footprint

9. Low electrical consumption

10. “One stop shopping”

High quality Biosubstrate

The end product from a BioPrePlant®-System is a biosubstrate that is suitable for anaerobic digestion. In the development of the BioSep® no resources were spared, to ensure optimal separation, which means that we can guarantee that the biosubstrate will be of the highest quality. The particle sizes of the digestible material, and the amount and sizes of the impurities remaining within the biosubstrate, is well within the technical and environmental requirements for utilizing the biosubstrate in biogas production and then the digestate as a bio fertilizer.

High quality Biosubstrate.

Metalpieces separated in the BioPreCrusher®.

Plastic and other foodpackaging material separated in BioSep®.

BioPrePlant®-System

The BioSep® is the core component of the BioPrePlant® System, which is a unique system for pre-treatment of food waste. Click here to learn more about the BioPrePlant® System.